PARAFIL® ropes consist of a core of closely packed, high strength aramid or polyester fibres, lying parallel to each other, encased in a protective polymeric sheath.

This structure is combined with a specially designed termination technique.

The combination of these two technologies produces ropes of immense strength, capable of meeting the requirements of even the most complex application.

PARAFIL® - documentation:

PARAFIL® - documentation:

Basic physical

Basic physical

properties

|

Electrical

Electrical

properties

|

Long term

Long term

properties

|

Technical

Technical

specifications

|

Flame Retardant

Flame Retardant

Sheath

|

Terminal - documentation:

Terminale Tipo F

Terminale Tipo F

|

Terminale Tipo P

Terminale Tipo P

|

Fulfill the contacts form to get the username and password for the private area of this site.

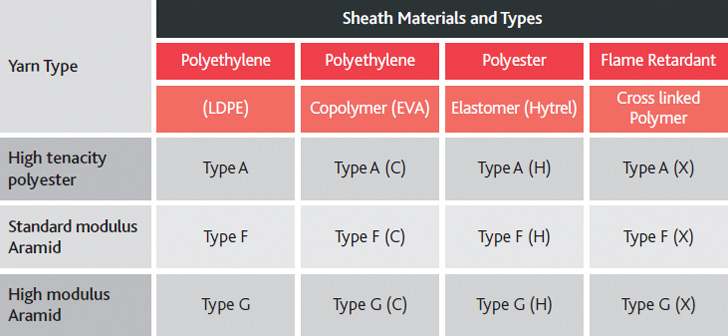

PARAFIL® types

There are three standard types of PARAFIL® available based on the type of fibre used for the core.

However, each of these is available with a choice of polymeric sheaths to suit varying applications.

These include a specially formulated polyethylene, which is suitable for most applications, an EVA copolymer that is more flexible and stress-crack resistant,and a polyester elastomer that offers higher resistance to heat and abrasion.

A flame retardant, cross linked polymer sheath is also available.

PARAFIL® FEATURES

• High tensile strength

• Low weight

• Easy to handle

• Good insulating properties

• Excellent tension-tension fatigue resistance

• High strength to weight ratio

• Low creep

• Virtually maintenance-free

• Unaffected by water, sea-water,

ice and other extreme

environmental conditions

PARAFIL® IN ACTION

Insulating guys, catenaries and support systems

The first applications for PARAFIL® ropes were in the antenna and electrical industries. PARAFIL® is used in insulating guys, catenaries and support systems where PARAFIL'S high tensile strength and insulating properties along with resistance to UV radiation ensures a long and virtually maintenance-free life.

The use of PARAFIL® in these areas has now been extended across the world. In each instance tailor-made PARAFIL® ropes and specially designed terminations are produced to meet each specific customers needs – no system is too complex for PARAFIL®.