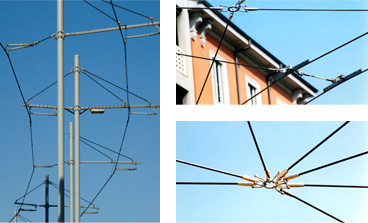

Supporting overhead sytems

A natural evolution from the antennae and electrical, Parafil® ropes have been selected to support tram and trolley bus overhead conductors. In terms of linear metres used, urban transport systems now represents one of the fastest growing markets for Parafil®.

From it'sintroduction in 1976 to the present day PARAFIL® rope has been providing first class service in supporting overhead contact wires for Light Rail, Tram and Trolley Bus transport systems.

The earliest commercial system, installed in 1976, continues to give trouble free performance in the summer heat and winter fog which is typical of the Italian city of Milan. One of the later systems is performing qually well in the crisp, cold and sometimes wet streets of Sheffield situated in the north of England. Other systems in the UK and Ireland include Manchester Metro, West Midlands, Croyden and Dublin. PARAFIL® is also used extensively through Europe in this application.

PARAFIL® has been used in many locations around the world to support overhead conductive cables for tram electrification.

PARAFIL® has been used as the material of choice to support Urban Transport Systems in the following locations; Alger, Athens, Bilbao, Brussels, Bucharest, Copenhagen, Dublin, Folkestone (Euro tunnel terminal), Geneva, Jerusalem, Liepaja, Lisbon, Liverpool, Lyon, Hong Kong, Madrid, Manchester, Marseilles, Melbourne, Nice, Odessa, Ohio, Oslo, Porto, Prague, Riga, Rome, Sheffield, Tenerife, Toronto, Turin, Valencia, Zurich and many more.

PARAFIL® consists of a densely packed core of high tenacity synthetic fibres laid in a parallel arrangement and encased in a black polyethylene sheath. Type A PARAFIL® has a Polyester core; Type F offers higher strength and modulus and utilises aramid fibre.

The primary advantages of PARAFIL® in these end uses are:

PARAFIL® is a dielectric allowing 'clean' system design without the use of ceramic insulators

PARAFIL® is a dielectric allowing 'clean' system design without the use of ceramic insulators- PARAFIL® ropes are characterized by an excellent vibration absorption

- PARAFIL® does not corrode and is highly resistant to environmental attack

- PARAFIL® is protected from UV degradation by its stabilised black Polyethylene sheath

- PARAFIL® has excellent fatigue performance

- PARAFIL® exhibits excellent thermal stability and a low creep

- The smooth, low friction surface of PARAFIL® reduces the build up of pollutants and prevents icing

- The overhead system that employ PARAFIL® are virtually maintenca-free