Industry and submarine research

Subsea Applications

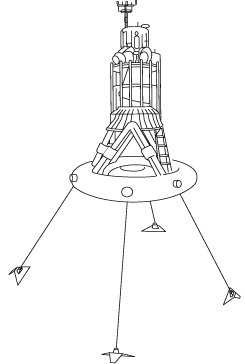

The corrosion resistant nature of PARAFIL® makes it an excellent choice of material for securing subsea structures. PARAFIL®has a high tensile strength and modulus along with desirable creep characteristics, high energy absorption and damping, good tension – tension fatigue life and thermal stability over a wide range of working temperatures.

A wide range of specially designed termination fittings allows PARAFIL® to be secured to almost any subsea structure. No system is too complex for PARAFIL®.

|

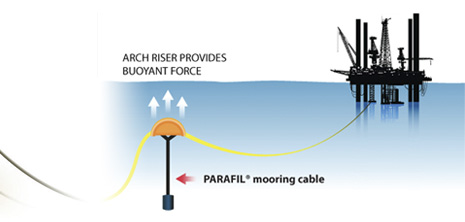

Subsea Arch Systems

Riser arches are used to provide a buoyant force to subsea pipelines which would otherwise fail under their own weight. PARAFIL® is used to moor the buoyant arch to the seabed or subsea structure. The high strength, durability, low creep and resistance to corrosion make PARAFIL® an ideal material for this application.

Advantages of using PARAFIL® over chain or steel wire include; neutral buoyancy, higher tenacity, lower weight and better durability.

|

|

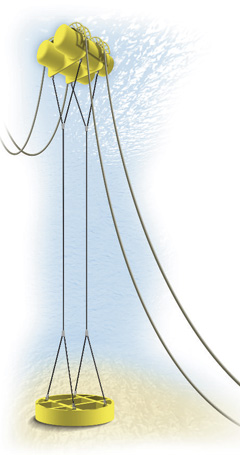

Buoy Mooring

PARAFIL® TypeA has given trouble-free performance in this demanding North Sea mooring application.

|

|

Subsea Buoy Mooring

PARAFIL® Type A was chosen to provide mooring tethers for the Teal and Guillemot subsea oil riser control buoys because of its weight, durability and the ability to produce tethers of exact length.

The body of supporting data, available from Linear Composites limited, also allowed accurate prediction of in-service performance.

This project saw the first commercial use of a spliced PARAFIL® end termination. On large Type A ropes this offers considerable weight and handleability advantages.

|

|